Ford Otosan achieves 3% savings using predictive digital twins

Project facts

- ClientFord Otosan

- LocationIstanbul, Turkey

- ChallengeWith a proposed design for a new facility, Ford Otosan wanted to determine whether the design could deliver the throughput needed to achieve production targets.

- SolutionAn ecosystem of digital twins using predictive simulation, where scenarios were run over short, medium and long-term periods to assess the effects over time and ensure targets could be met.

- ImpactWorking with Twinn Witness Horizon software, Ford Otosan achieved 3% savings on their proposed electric vehicle factory and could plan for production capacity 12 months on from opening their new facility.

With the help of Twinn Witness simulation modelling, it is a great advantage to verify the feasibility of new production facility projects and to see opportunities before investment realisation."

The company has extensive experience in digital factories and data-driven production processes. In this project, our partner in Turkey, CodeArt, supported Ford Otosan to leverage predictive simulation in the design process for a new electric transit vehicle factory.

The challenge

Will the proposed factory layout achieve production targets?

A key benefit of predictive digital twins is the ability to de-risk capital investment projects. And that’s exactly what Ford Otosan was looking to do. They had designed a layout for the newly planned facility, and wanted to determine whether that design would deliver the throughput needed to achieve production targets.

Validating the design required answers to key questions such as:

- Would station cycle times align with forecasts?

- How efficiently would robots perform over time?

- How would breakdowns affect the system?

- What buffer capacities would be required to maintain required production levels in the event of a breakdown or failure?

The factory design involved complex cyberphysical systems, and Ford Otosan wanted to ensure it was planning its investment in machinery, robotics and operators in the optimal way.

The solution

An ecosystem of predictive digital twins

Ford Otosan designed the facility in 3 sections:

- Welding and vehicle body production

- Paint shop

- Assembly

Leveraging more than a decade of experience, CodeArt developed models using Twinn Witness Horizon predictive simulation software from Lanner. They started with the welding and vehicle body production lines. First, a model was created for each line to get an in-depth understanding of cycle times, robot and operator performance, downtime and buffer requirements. Then, these detail models were fed into an integrated model used to test the section’s complete layout.

The predictive digital twin was used to analyse a wide range of scenarios. For example, CodeArt tested many vehicle types to determine the effect of different sequencing on throughput. They looked at the distribution of robots and operators across peaks and troughs in production. Equipment levels were analysed to see if they could achieve the projected cycle times. And a range of best- and worst-case breakdown scenarios were evaluated to understand the knock-on effects and required buffer capacities.

Importantly, scenarios were run over short, medium and long-term periods to assess the effects over time.

The impact

3% savings – and confidence the layout will achieve its targets

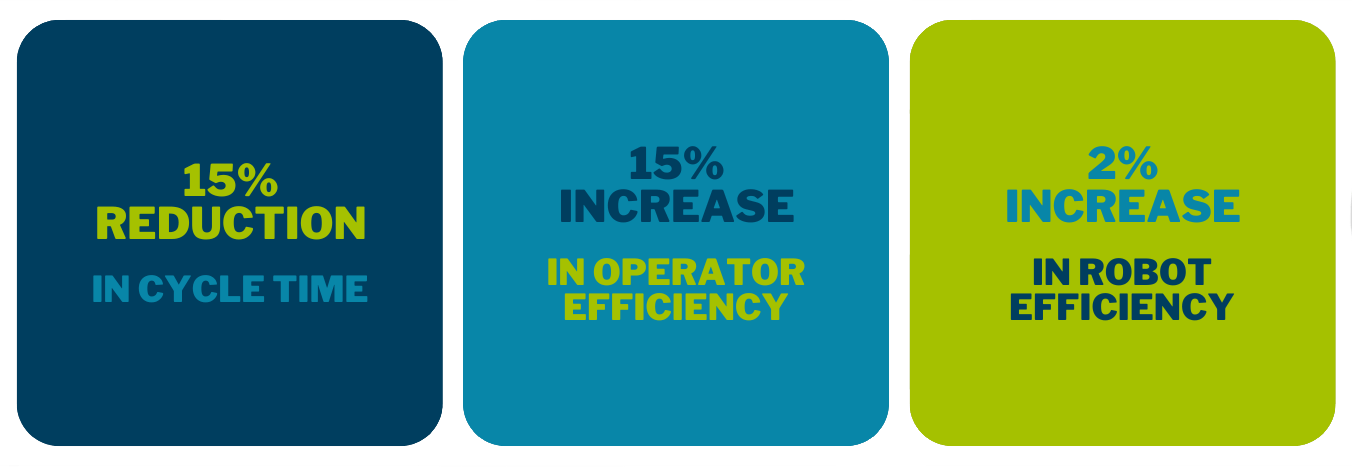

Using the Twinn Witness models for the welding and vehicle body production lines, Ford Otosan was able to optimise its design.

- Previously unidentified bottlenecks that were resolved

- A smart production algorithm to plan the sequencing of vehicle types

- Opportunities to achieve robot and operator efficiencies

- Cycle times that were out of sync with forecasts and could be improved

- Preventative measures to mitigate the effects of breakdown

“Simulations are now indispensable for building high-efficiency lines at the design stage. Our high-tech production lines, where we will produce electric vehicles, will have simulations that are used not only during the design phase, but also after mass production starts. These simulations will turn into a decision support system by processing real-time production data. We are proud of commissioning a digital twin project for the first time at Ford Otosan,” said Omer Faruk Senocak, Data Analytics and Simulation Engineer at Ford Otosan.

Based on the success of this project, Ford Otosan and CodeArt are now using Twinn Witness to build predictive digital twins of the paint shop and assembly lines, ultimately providing an integrated simulation model of all manufacturing processes for the electric transit factory. This will enable simulation to be a cornerstone of Ford Otosan’s ongoing operational planning, helping them leverage data and Internet of Things investments in line with their digitalisation strategy.

“With the help of Witness simulation modelling, it is a great advantage to verify the feasibility of new production facility projects and to see opportunities before investment realisation. We are also taking the most important step towards digital twinning with Witness,” said M. Nejat Tanca, New Technologies and Smart Factories Leader at Ford Otosan.