Helea® - Advanced anaerobic digestion technology

Combining biological hydrolysis and pasteurisation, Helea dramatically increases biogas production and reduces a plant’s carbon footprint through efficient use of surplus energy as renewable power and heat generation. It transforms the remaining biosolids into soil conditioner to use safely in agriculture.

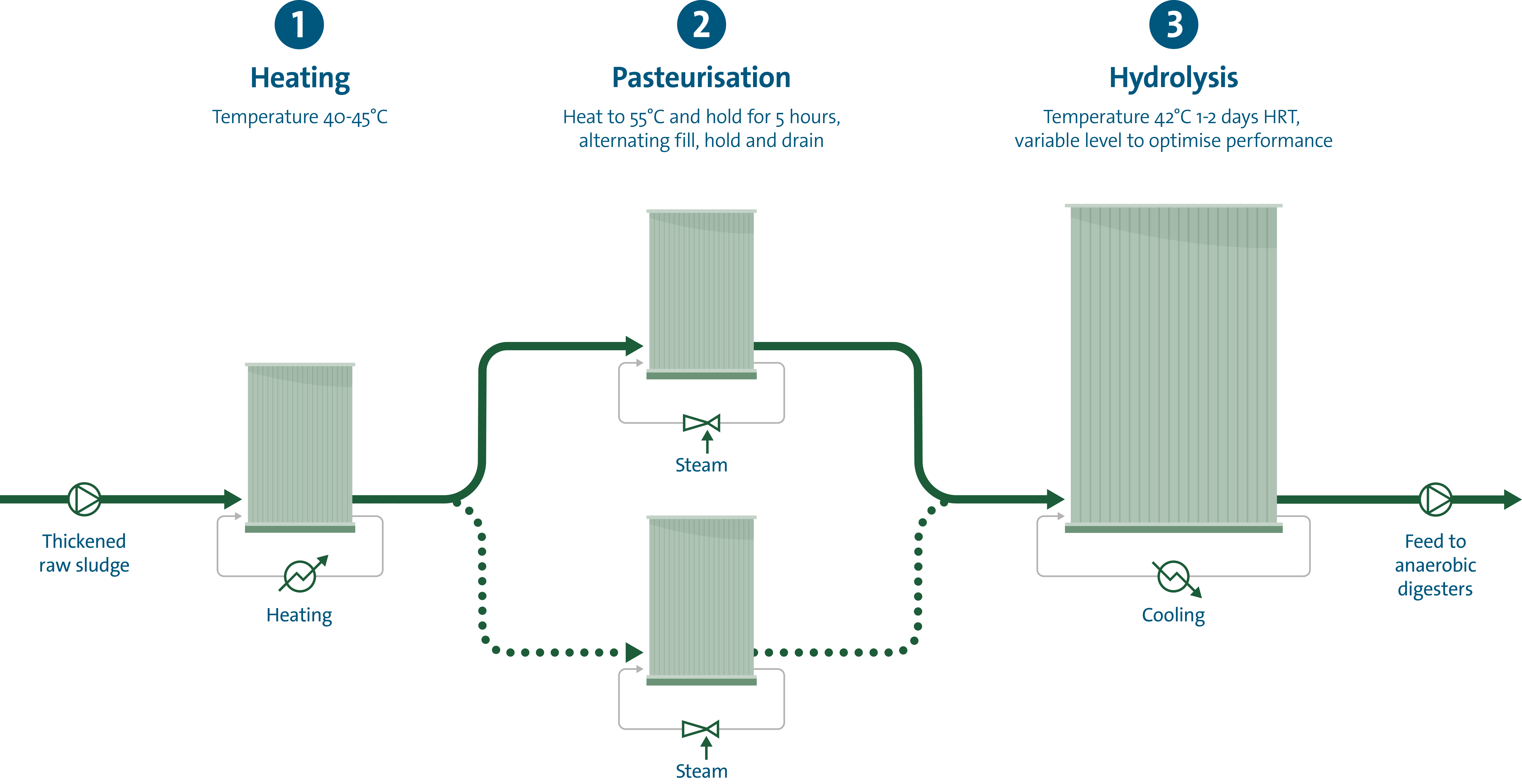

Helea is a simple and reliable three stage process, involving heat recovery, pasteurisation and biological hydrolysis. Effective integration of these steps with specially developed process monitoring and control features have resulted in industry-leading levels of availability, safety, flexibility and energy efficiency.

Proven track record

Originally developed by Anglian Water, Helea is an established technology, with a proven track record of over eight years in the UK water industry, in a wide range of operating conditions. Compared with other advanced sludge digestion procedures, Helea is more sustainable and energy self-sufficient. It delivers significant, sustainable capital and operational savings. Proven to generate a ‘best in class’ high yield of approximately 1 MWh renewable electricity from the biogas produced per dry tonne of process biosolids, it supports our driving ambition to enhance society together.

Helea provides

Operational carbon savings

Pasteurised enhanced quality biosolids for safe recycling to agriculture

Competitive CAPEX and significant OPEX savings

The process

Sludge is heated by recovered heat and steam is injected into it to raise the temperature for the pasteurisation step. No additional support fuel is needed, making the process energy self-sufficient and optimising carbon benefit. Buffering the sludge through the process ensures optimum performance, stability and reliability. As the process does not require high pressure for hydrolysis, there is no need for annual scheduled downtime for safety checks and maintenance.

Introducing Helea® – Helping you on the route to Net Zero 2030

The benefits

Helea can be added upstream of existing digesters, allowing them to operate at a significantly increased organic loading rate, solids destruction and biogas yield.It separates the sludge digestion into two phases (hydrolysis and methanogenesis), enabling digesters to break down more organic solids and produce increased levels of biogas, with reduced CAPEX and increased operational savings.

With the industry moving towards sustainable ‘biomethane to grid’, low carbon heat recovery systems can be integrated into the process. This maximises biomethane flow to grid, delivering higher levels of efficiency and operational savings, enabling integration of modern low carbon heat recovery solutions, such as heat pumps, in place of CHP engines. This maximises biogas revenue, further progressing towards energy self-sufficient wastewater treatment.

Operational benefits

- Saves money and reduces carbon footprint, helping meet Net Zero targets

- Maximum efficiency in biogas production

- Operational carbon savings

- Simple process, easier to operate and maintain compared to other pre-treatment technologies

- Less energy required for process heating

- Direct steam heating for pasteurisation

- Built-in flexibility to deal with variations in load, and sludge quality

- Advanced control for optimum performance and modern remote monitoring

- Operational flexibility for optimising performance in terms of increased solids destruction and biogas yields, and recycling of enhanced quality biosolids

- High availability, no routine shutdowns of plant required

- Supports lowest carbon option, such as ‘biomethane to grid’ and alternative heating sources

- Health and safety benefits due to lower operating temperatures without elevated pressures

- No odour nuisance, fully contained process

Our projects

Basildon

10,300 TDS/yr

Commissioned 2013

15,000 TDS/yr

Commissioned 2014

15,000 TDS/yr

Commissioned 2014

17,500 TDS/yr

Commissioned 2014

Want to know more or got a question?

Contact our BioResource experts!