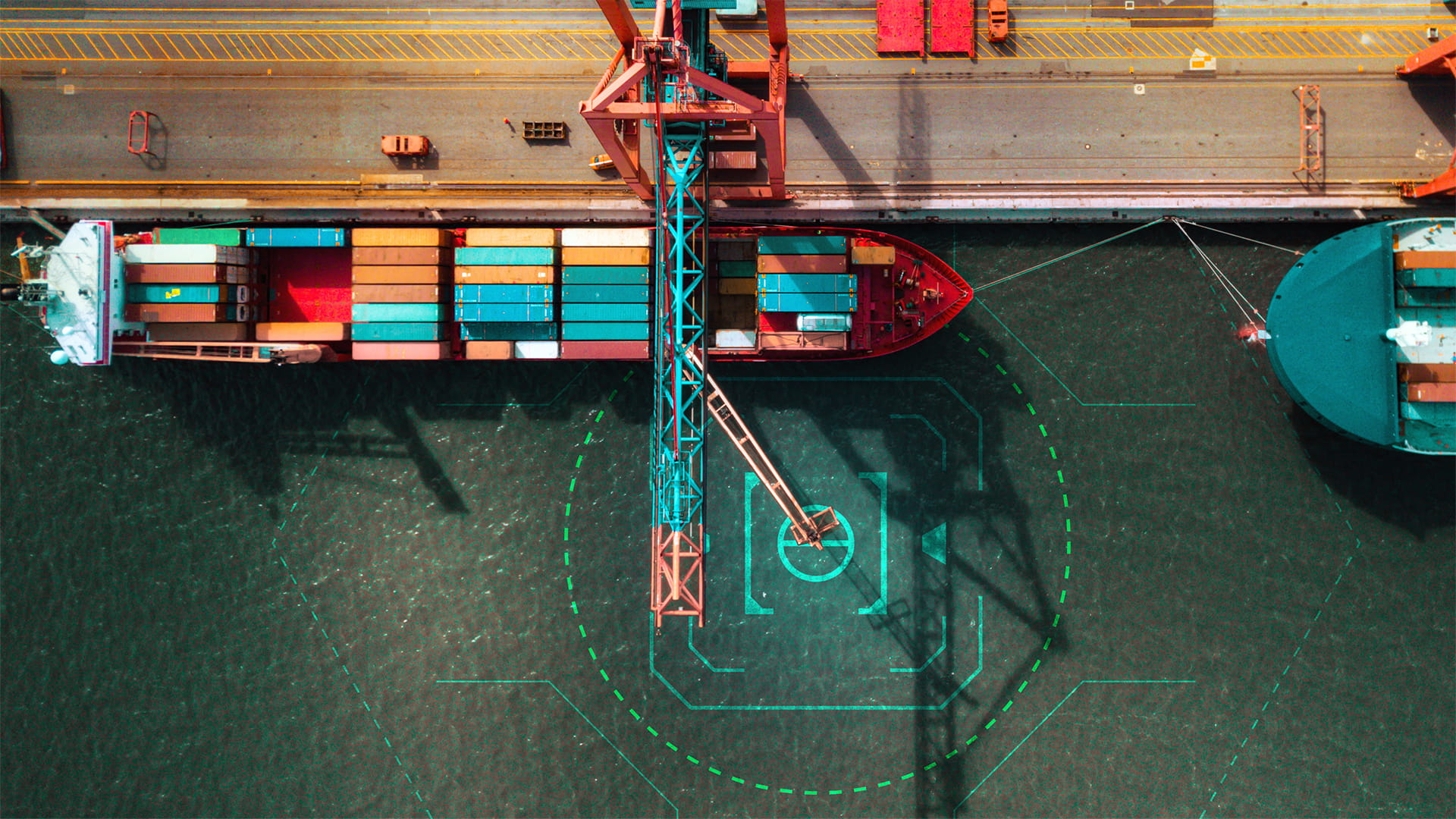

Safe mooring of ultra large container ships (ULCS)

Project facts

- ClientPort of Rotterdam

- LocationRotterdam, the Netherlands

- Date2021 – 2022

- ChallengeThe Port of Rotterdam needed to adapt its operations to safely accommodate Ultra Large Container Ships.

- SolutionA Dynamic Mooring Analysis established the best steps for significantly improving mooring safety.

The challenge: larger vessels required a deeper port

Port of Rotterdam intended to deepen one of its port basins to receive Ultra Large Container Ships (ULCS). Our experts supported Port of Rotterdam by checking the quay wall stability and strength for the intended deepening – including the consequences of the associated new functional requirements.

The port wanted to carry out a Dynamic Mooring Analysis for the ULCS to ensure appropriate and safe mooring facilities. Specifically, it wanted to analyse mooring loads generated by larger vessels and establish in what wind conditions bollard capacity would be exceeded.

The solution: conditions analysed to maximise safety and uptime

We analysed the behaviour of a ULCS in wind to review bollard load limits and identify the wind limits that would exceed them. We also included ShoreTension® mooring system in our calculations and found that it could help reduce the downtime caused by overloading bollards from an average of four times per year to once every 15 years.

Considering various wind directions, our analysis established the ideal number and position of ShoreTension® units to ensure the safe mooring of ULCS.

DMAs enhance the safety of our moorings and sometimes allow larger ships to berth safely by optimising existing infrastructure. This approach is far more sustainable and cost-effective than developing new infrastructure.

The result: safe mooring for ULCS

Our deep insights into the mooring behaviour of ULCS has helped the Port of Rotterdam enhance its port safety and operational uptime.

Port of Rotterdam obtained a proposed layout for additional bollards required for the recommended use of ShoreTension®. It boosted safety and limited potential disruption with this analysis.