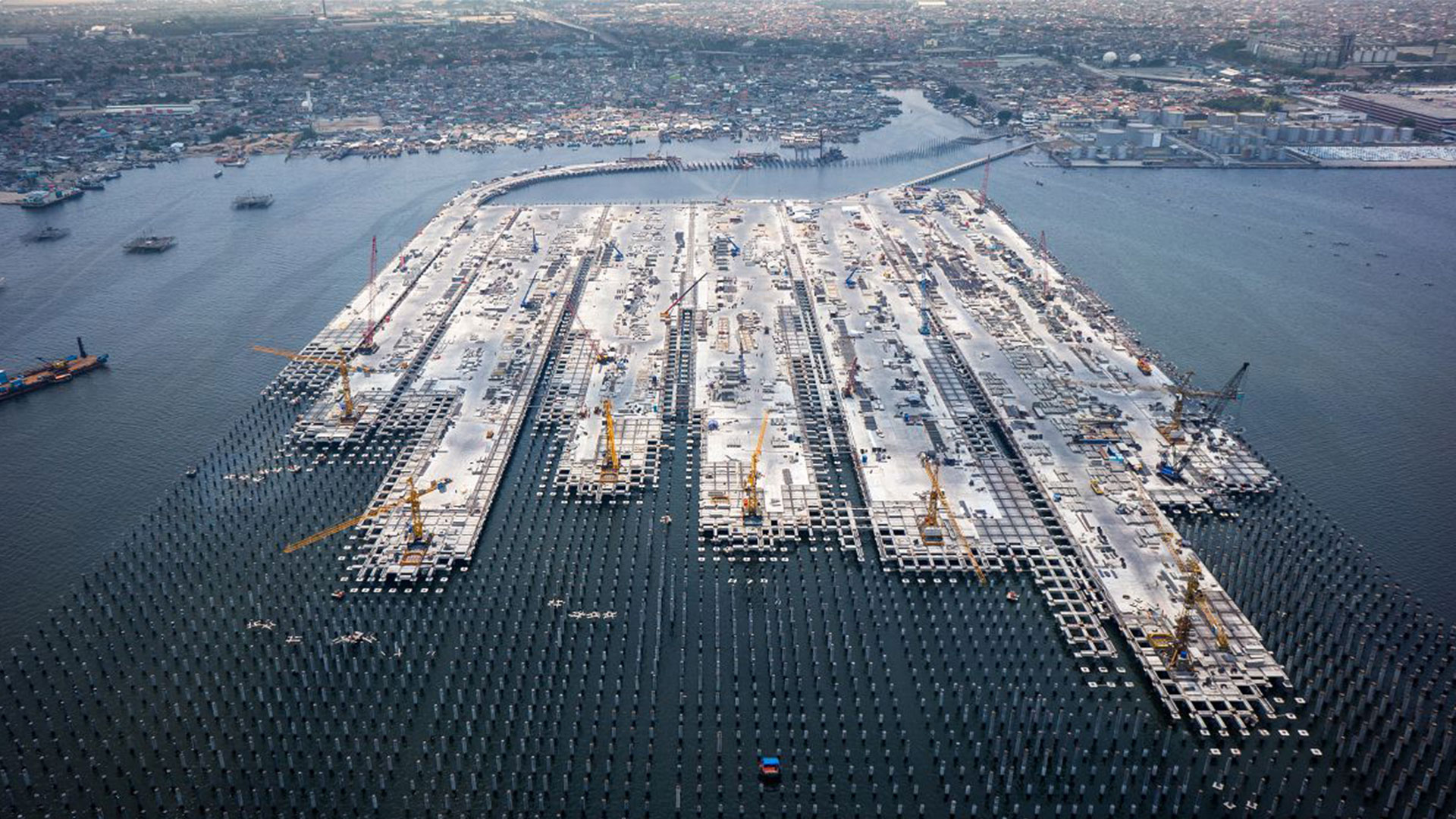

Major container terminal development in Vietnam

Project facts

- ClientGemadept-Terminal Link Cai Mep Terminal JSC (Gemalink; a joint venture of “Gemadept JSC” and “CMA Terminals”)

- ChallengeRedesign of a partially constructed jetty utilizing the already installed 259 piles to accommodate larger future container vessels (25,000TEU).

- LocationCai Mep River, Ba Ria Vung Tau Province, Vietnam

- SolutionCombining our vast marine expertise with digital ways of working, in order to create a final design that maximises efficiency and reduces materials.

When the works were stopped in 2012, the engineering, procurement and construction (EPC) contractor had completed the design and most of the reclamation works – as well as installing 259 out of 1,895 piles for the jetty. In 2017 the project was restarted and Royal HaskoningDHV was contracted again by Gemalink as the Owner’s Engineer.

The challenge: redesign of a partially constructed jetty

Gemalink wanted to tender the civil marine works of the Jetty as a Construct Only type of contract and requested Royal HaskoningDHV utilise the already completed detailed design by the EPC Contractor. Due to the current and expected development in size of container vessels to be ready for the future Gemalink wanted to be able to receive up to 25,000TEU container vessels (250,000DWT) in the future at one of their berths.

Considering the future container vessels and the fact Royal HaskoningDHV could not take on responsibility for the existing design by the EPC Contractor, it was agreed with Gemalink to undertake a redesign of the Jetty, but the redesign had to incorporate the already existing 259 piles installed.

The solution: combining our marine expertise with digital ways of working

The previous installed piles were first surveyed and tested in detail to understand the condition of these piles. Based on the test and survey results, we included the exact location, orientation and condition of these piles in the new design. The latest design codes (British Standards/Eurocodes) were applied to maximise design efficiency and minimise the use of materials and resources. All the assumptions made in the initial 2010 EPC Contractor’s design were revisited to identify potential cost savings.

The project was undertaken in the BIM Environment using 3D modelling (Revit, Civil 3D) and included state of the art design calculations and methodologies.

Since the early Feasibility stage of the project achieved over 10 years ago, Royal HaskoningDHV has proven to be a reliable technical partner by our side, consistently bringing value at each steps of the development process in the most professional manner.

The result: completed detailed engineering design of the civil marine works

The completed detailed engineering design of the civil marine works provided Gemalink with a Jetty that is fit for future use (able to accommodate larger future vessels) whilst significantly reducing the construction risks and cost (overall project costs were reduced by 10%; compared to the design by the EPC Contractor).

A blend of marine expertise and the use of the latest digital tools delivered multiple outcomes:

- Simplified overall design, maximizing the use of precast concrete elements

- Simplified scour protection at the berths

- Replaced deep-soil cement mixing at the access trestle abutments with bored pile wall

- Reduced the number of piles

- Removed the cathodic protection system by using a protective sleeve system on the steel piles

- Replaced the access trestle end detail with a simple transition slab

Maximising the use of precast concrete elements significantly improved the quality, safety and ease of construction and overall construction period of the project.

In addition to the design, Royal HaskoningDHV handled the tender process and worked with Gemalink closely to devise a best approach and type of contract for the construction works. This approach combined with a well-developed design helped Gemalink to achieve cost-effective bids from multiple contractors (including local and international contractors) and brought further cost savings to the project.

Following the completion of the detailed design of the civil marine works, RHDHV was awarded the construction management services for the marine and onshore works. The civil marine works were completed in January 2021 and the final total construction costs were within the contracted lump sum fee for the works. The onshore works were completed in September 2021.

For the design, engineering, tendering and construction project management services for the GemaLink International Container Terminal, Royal HaskoningDHV has won the 2021 Award of Merit in the ENR Global Best Projects Competition, in the category Ports/Airports.