Greenfield brewery in Vietnam sets standards for integrated 3D modelling

One of the first greenfield brewery projects in Vietnam using fully-integrated 3D models and digital tools showcased the benefits for our client.

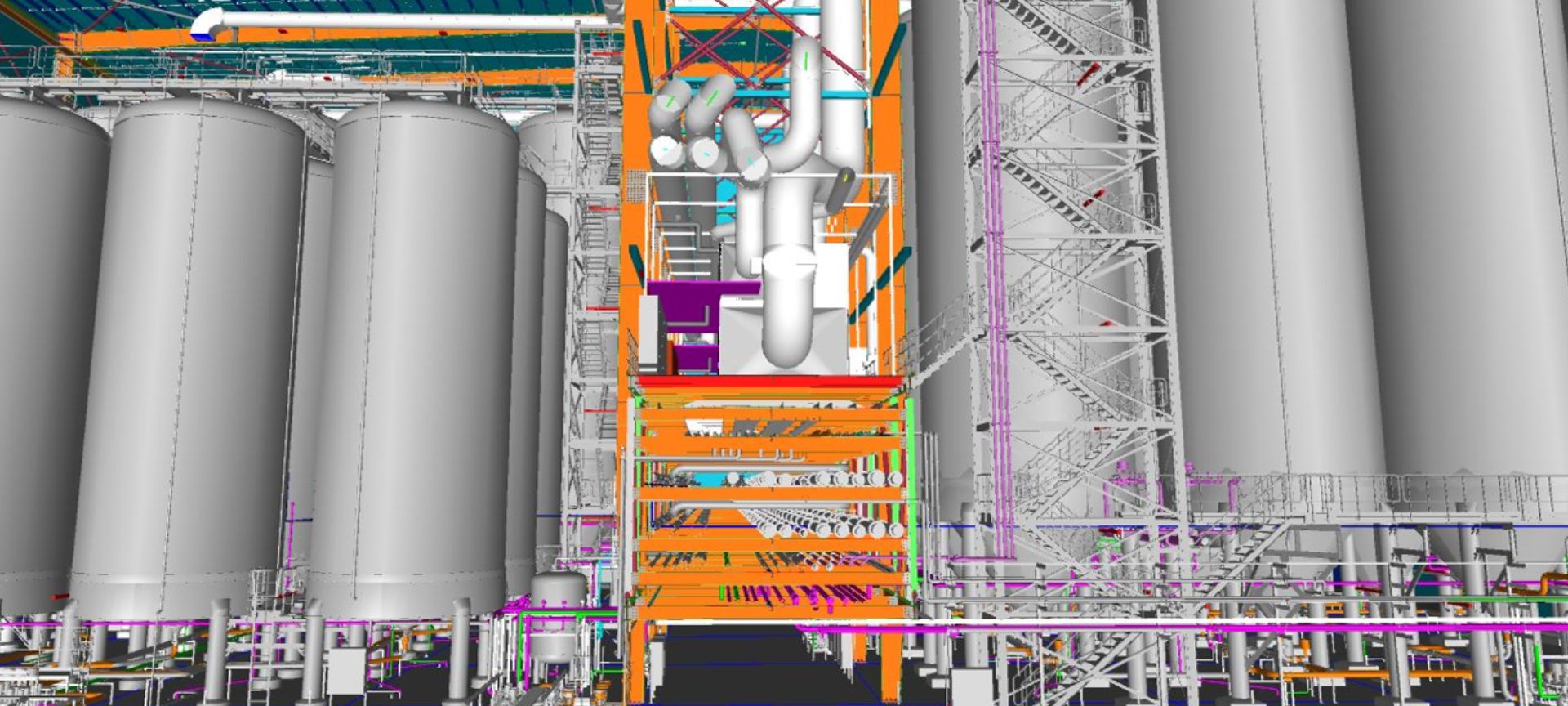

Our client was constructing a new greenfield brewery in Vietnam and required us to manage and integrate 3D models - including process equipment - within the Building Information Model (BIM). At the time such tools were not widely used on this scale so it was a learning process for our client and for equipment suppliers too. To ensure successful execution and on-time delivery, we took the lead in guiding and assisting our client and stakeholders.

3D model provides 100% accuracy to solve issues and clashes in advance

To overcome the fact that many equipment suppliers lacked the necessary tools or expertise, we carried out checks and corrected external models to ensure they could be integrated into the single model.We knew from experience that a potential bottleneck was the information flow between our design team and equipment suppliers, so a member of our team was located in our client’s office to streamline the flows. This is a good example of how we anticipate and facilitate issues, doing whatever we can to keep the project moving forward on schedule.

Our integrated model included the pipe bridge and all the process piping to ensure there were no clashes between pipework and structural elements. The benefit of a fully integrated 3D model lies in the accuracy of the representation. Every structure and feature in the model are 100% accurate with regard to dimensions and location in reality.

We took the lead to drive the development of BIM and 3D integration. As a result, it was clear to our client how 3D modelling contributed to a successful outcome. We helped them identify how to formalise requirements for the exchange of data in future projects, taking us well beyond the traditional civil scope.

Project facts

- LocationVietnam

- ChallengeOur client was constructing a new greenfield brewery in Vietnam and required us to manage and integrate 3D models - including process equipment - within the Building Information Model (BIM).

- SolutionTo overcome the fact that many equipment suppliers lacked the necessary tools or expertise, we carried out checks and corrected external models to ensure they could be integrated into the single model.