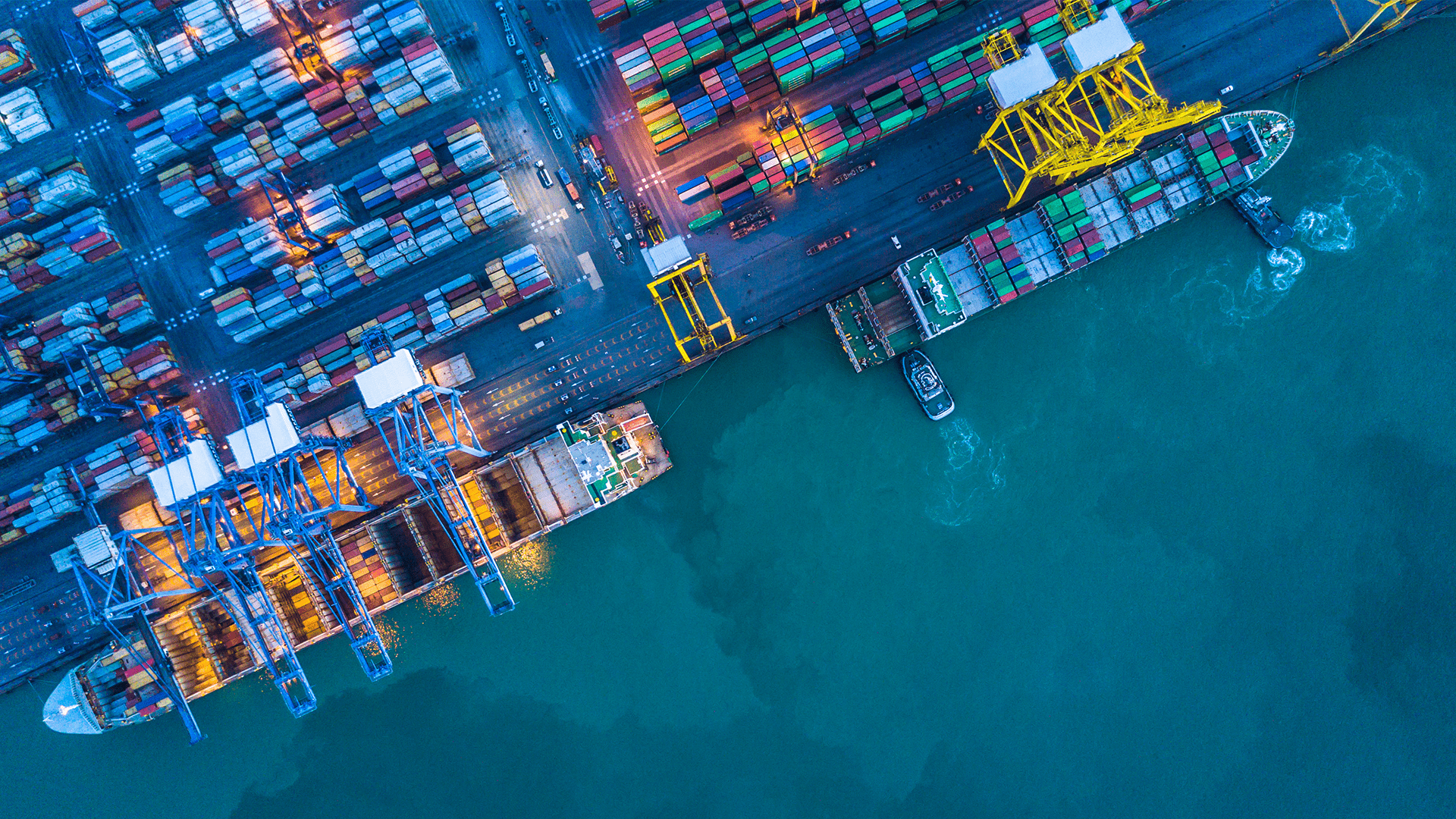

Future-proofing terminal operations in New Zealand

New Zealand’s largest container terminal needs to increase its capacity to enable future trade growth, but faces expansion limitations. Discover how our container terminal experts are enhancing the terminal’s capacity and operations with automation.

Contact usContact us

Project facts

- ClientPort of Tauranga Limited

- LocationTauranga, New Zealand

- DateApril 2022 – ongoing

- ChallengeOptimising terminal operations and capacity in a constrained environment

- SolutionIntegrating automated equipment and technology to enhance operations

The challenge: optimising terminal operations and capacity in a constrained environment

Tauranga Container Terminal is New Zealand’s largest container terminal by throughput. Handling 41% of the country’s shipping containers, it serves as New Zealand’s primary international trade link, connecting the country to the rest of the world.To unlock future trade and economic growth, Port of Tauranga Limited (POTL) needs to increase the terminal’s capacity but faces challenges due to constraints on physical expansion and existing operations.

The solution: enhancing operations with port terminal automation

POTL is planning to phase in automated stacking cranes to replace manual straddle carriers - increasing the terminal’s stacking density and capacity - while investigating additional automation solutions to further optimise its operations.In 2022, POTL engaged Royal HaskoningDHV as an embedded partner to provide expert technical advisory services across many aspects of the automation project.

To date, we have assisted POTL with terminal masterplanning by analysing various layout options and staging plans, and have supported the preparation of tender documentation and subsequent procurement of the automated stacking cranes.

We have also worked closely with POTL to review its existing gate processes, and are now assisting with the development of a new and improved gate that incorporates automation technology and infrastructure.

As the project moves forward, we - along with our key project partners, IGO Solutions and Complexica - will continue to provide expert advice and consulting services to transform the terminal’s operations.

The Royal HaskoningDHV team have been great. They have provided significant value to the project through their knowledge and experience.

The result: increased port terminal capacity and more sustainable operations

Upon completion, the project is expected to yield numerous benefits, including increased capacity without expanding the terminal’s footprint, reduced operating costs, significantly decreased CO2 emissions, and improved safety – as most employees will be in supervision and management roles rather than machine operation.As a result of automated operations, Tauranga Container Terminal’s performance will be more stable and predictable, and it will be able to handle future capacity demands, supporting the economic growth of New Zealand as a whole.