Digital twin provides resilience to coastal change

Using the innovative sand engine approach, Royal HaskoningDHV worked with the terminal’s operators and the local authority to build a nature-based solution that will protect the terminal and surrounding areas for another 15 years. Royal HaskoningDHV developed a custom-built digital twin of the beach to optimise long-term management of the beach. This will help make the terminal and the villages resilient to long-term coastal change.

Project facts

- ClientNorth Norfolk District Council (NNDC), Bacton Terminal Companies, Environment Agency, Supported by The Netherlands’ Government’s Partners for Water innovation programme

- LocationBacton, Norfolk, UK

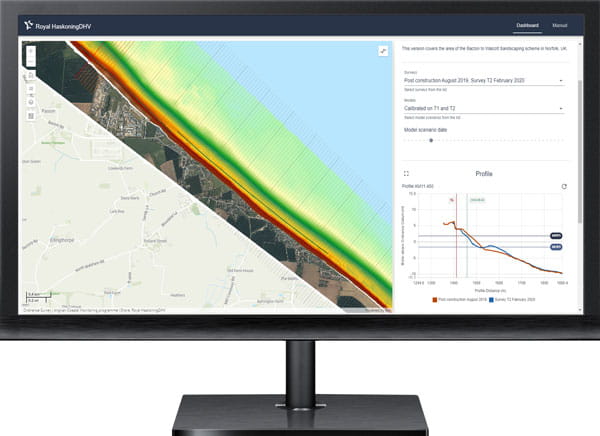

- SolutionA digital twin helps leaders, coastal managers and other experts understand how the new beach performs, and uses predictive models to plan next steps after the scheme’s functional life.

- ChallengeHelp mitigate the impact of coastal erosion and storm surges to protect critical energy infrastructure and local homes and businesses.

Results

Reduced risk to infrastructure

Protected local communities from flood damage

Cut consultancy costs with automated analysis

The challenge

Mitigating the impact of coastal change

The Bacton gas terminal, situated on the North Norfolk coastline in England, provides a third of the UK’s gas supply via pipelines fed from North Sea platforms and the continent. When the terminal was built in 1967, it was positioned 100 metres from the cliff edge.

As decades passed, coastal erosion reduced that distance to just 10 metres in 2013. Part of this dramatic loss was due to a severe storm surge in 2013, which also flooded homes in the nearby villages of Bacton and Walcott.

The coastline’s existing sea defences were expected to fail within 10 years, putting critical national infrastructure and nearly 300 homes at risk. So, in 2014, the Bacton terminal companies and North Norfolk District Council approached Royal HaskoningDHV to find a new solution.

The solution

Leveraging digital twin predictive models for optimal natural asset performance

Using ‘hard’ defences, such as concrete, would have protected the Bacton gas terminal but created further issues for the villages. Hard defences would retain sand in front of the terminal, which would exacerbate the beach loss at Bacton and Walcott, leading to their sea wall and road failing more rapidly.

The project needed an innovative, integrated scheme that could protect both the terminal and the villages. Inspired by the Dutch sand engine (zandmotor) scheme, the team placed 1.8 million cubic metres of sand along 6.5 kilometres of frontage, increasing the height of the beach by between 3 and 7 metres, and the width by up to 100 metres in front of the terminal

To achieve this, Royal HaskoningDHV built a digital twin of the new beach. This uses surveys of the sand and data for the conditions that affect it, to update the design prediction of functional life. This gives Bacton terminal companies and North Norfolk District Council the power to make informed decisions for the next few decades.

Based on the insights so far, the system predicts that the next set of measures will be needed around 2034, 15 years after the beach was created.

The result

Getting insights into natural asset performance with digital twins

The sand engine’s digital twin automates a sequence of vital monitoring tasks: data management, modelling, prediction and presentation.

The digital twin uses data from advanced physical surveys to create and present predictions to help the terminal’s operators and the local authority make decisions about when and how to make their next investment.

Working closely with Bacton terminal companies and North Norfolk District Council to co-create a tool that fits their exact requirements, Royal HaskoningDHV added to the twin’s core predictive functionalities with a visual interface for the present day monitoring results. Royal HaskoningDHV secured co-funding of the digital twin’s development from the Dutch Government’s Partners for water innovation programme.

This enables the beach managers to build bespoke visualisations of their survey results, to help decision-makers understand how the sand moves.

Our digital twin helps the Bacton terminal companies and North Norfolk District Council make better-informed decisions for the situation after the end of the sand engine’s functional life. It’s a critical decision – the wrong choice could put the UK’s gas supply and almost 300 homes at risk.

Informed decision making with digital twin implementation

The sand engine was designed to defend against erosion and surges for the next 15 years, giving the terminal’s leaders, coastal managers, and the local residents’ peace of mind as they work and live. It also gives them time to prepare for inevitable future coastal change.

The digital twin is also helping the clients save time and money on the analytics work, reducing their reliance on consultancy and giving them instant access to critical information. In turn, that’s helping them make more intelligent solutions about the future of the terminal.

There is now scope to expand the digital twin’s capabilities beyond just monitoring the sand. For example, adding more sand to the beach changes how the current behaves, so the twin’s predictions could be used to pinpoint safe areas to swim based on weather and tidal conditions.

For the residents of Bacton and Walcott, the sand engine has bought time to adapt to coastal change and created a sense of safety. Even if there’s a storm, they know that their sea wall and promenade is protected, and their homes won’t flood.

The project has restored much of the beach that had disappeared over the last 30 years, giving the residents a scenic space once more – and boosting the local economy.

As the first project of its kind in the UK – and only the second in the world – North Norfolk District Council and the Bacton terminal companies have demonstrated they are forward-thinking clients, becoming early adopters of digital twins for coastal management alongside Bacton terminal companies.

Do you want to know moreor have a question?

Contact our experts!